PRODUCT

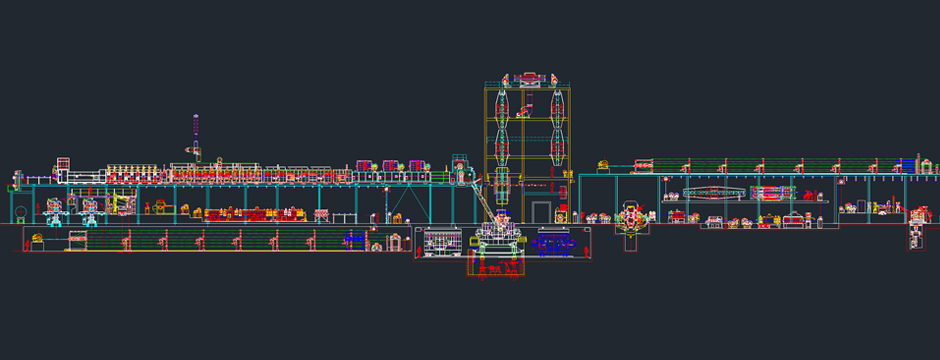

Continuous Galvanizing Line (CGL)

CONTACT US

MAS Group

Delhi Office:+91 9711200181

+91 9811060043, +91 9811087304

Mumbai Office: +91 9920645691

+91 9769197168, +91 9987007936

Email: r.singh@masgroup.in

m.ladole@masgroup.in

m.ladole@masgroup.in

CONTINUOUS GALVANIZING LINE (CGL)

| Input Material | Cold rolled steel / Hot Rolled & Pickled Steel |

| Strip Thickness | 0.1 – 3.2 mm |

| Strip Width | 600 – 2000 mm |

| Coating | Zinc (GI), Galvalume - GL, Galfan - GF, Al-Si |

| Type | Non Ox furnace Wet Flux |

| Speed | upto 180 mpm |

| Output Strip Quality | Full Hard (FH), Commercial Quality (CQ), Drawing Quality (DQ), Deep Drawing Quality (DDQ) Extra Deep Drawing Quality (EDDQ) |

Salient Features

- Auto loading of coils at Payoff Reals

- Welder for continuous operation

- Accumulators at Entry & Exit for Continuous operation of process section

- Degreasing section ( or optionally Electrolytic Cleaning)

- Non-Ox furnace with output qualities as FH, CQ, DQ, DDQ etc.

- Ability to process thinner gauges in Non-Ox furnace

- Non-Ox Furnace with Non-Water Cooled Rolls in the direct fired section thus saving on the fuel consumption.

- Final products are complying with all national & international standards

- Latest design of Air Knife to achieve lower Zinc coating thickness.

- Non-contact Leaser sensor type baffle arrangement for thinner gauge.

- Inline Coating Thickness Gauge

- Induction Pot / Metallic Pot for melting Zinc

- Lifting & shifting mechanism for changing pot during GI, GL & zero spangle.

- Movable Pendent for cooling Al+Zn Coating (GL)

- Inline Wet type Skin Pass Mill (SPM) & Tension Leveler (TL)

- Chromating & Anti-Finger Print Coating with Dryer & Cooler

- Oiler

- Recoiler with Belt Wrapper