PRODUCT

Galvanising Furnace

CONTACT US

MAS Group

Delhi Office:+91 9711200181

+91 9811060043, +91 9811087304

Mumbai Office: +91 9920645691

+91 9769197168, +91 9987007936

Email: r.singh@masgroup.in

m.ladole@masgroup.in

m.ladole@masgroup.in

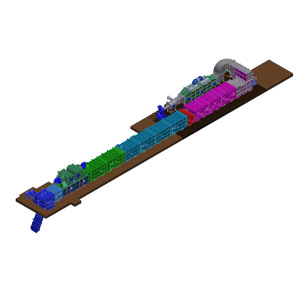

GALVANISING FURNACE

Salient Features

- Horizontal, ‘L’ Shape, & Vertical Design

- Non-Ox Type Process

- Non-Ox Furnace suitable for processing very thin gauges (0.15mm)

- Non-Water Cooled Roll Design

- Gas Fired & Electrical Radiant Tube Section

- Horizontal & Vertical Soaking as per the requirement of product

- Jet Cooler with electric Heaters for processing thin strips

- Furnace Bridle to maintain differential Tension

- Furnaces suitable for GI & GL production

- Special design of Calm Zone for arresting of Zinc Fumes in case of GL production

- Heated Down Chute for GL Production

- Flexibility in operation

- Strip Temperature Control and Zone Temperature Control

- Protective Atmosphere Control